The food and drug administration fda has stated that ethylene vinyl acetate is safe when used in food production packaging or transportation and it s not an especially dangerous material.

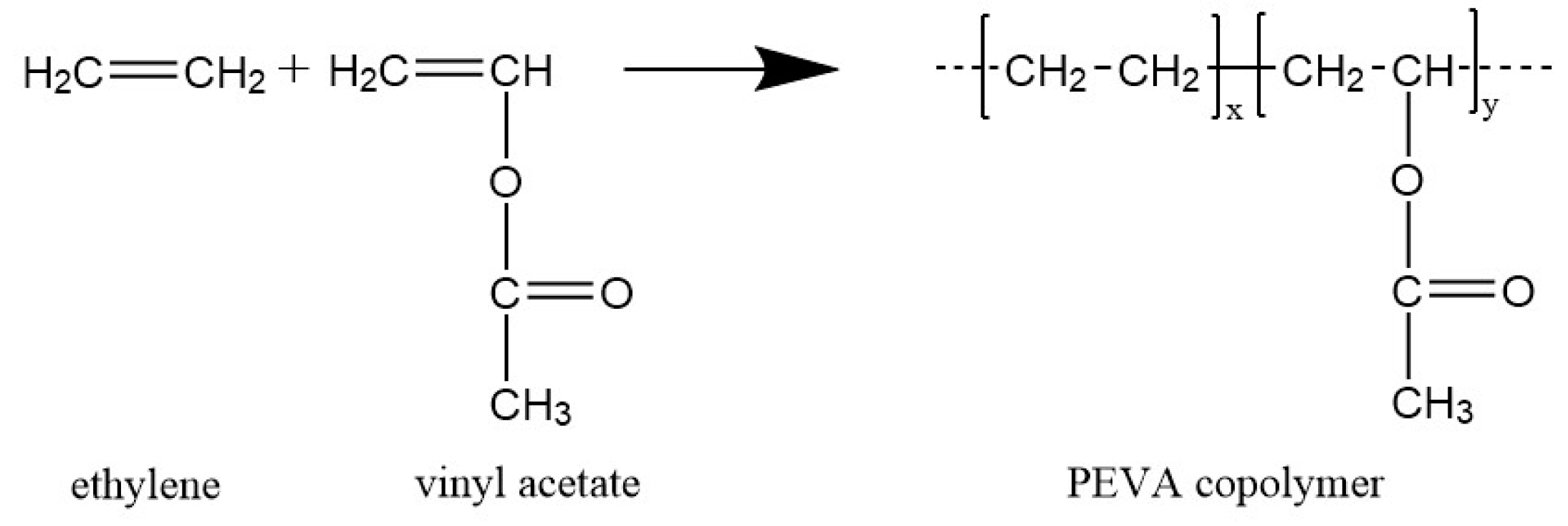

Ethylene vinyl acetate copolymer synthesis.

Before proceeding with drug incorporation evac must be washed in absolute ethyl alcohol to extract its inflammatory impurities mainly the antioxidant butylhydroxytoluene bht.

This work also successfully addresses the precision design of eva containing block copolymers i e.

Elvax 40p was obtained from the du pont company wilmington de.

George wypych in handbook of odors in plastic materials second edition 2017.

Ethylene vinyl acetate copolymers evas with low dispersities and ethylene content reaching 57 mol are notably reported.

Vinyl acetate ethylene vae is a combination of ethylene and vinyl acetate two monomers possessing special properties as e g.

The ethylene vinyl acetate copolymer evac 40 vinyl acetate by weight.

Us2703794a us245079a us24507951a us2703794a us 2703794 a us2703794 a us 2703794a us 245079 a us245079 a us 245079a us 24507951 a us24507951 a us 24507951a us 2703794 a us2703794 a us 2703794a authority us united states prior art keywords ethylene vinyl acetate weight copolymer water prior art date 1951 09 04 legal status the legal status is an assumption and is not a legal conclusion.

In this case the order of the synthesis of the blocks is a key parameter.

Eva based hot melts are able to fulfill various requirements in applications such as packaging bookbinding or label sticking.

Ethylene vinyl acetate copolymer does not have an acid odor if it is not thermally degraded.

Selectophore 91 vinyl chloride 3 vinyl acetate 6 vinyl.

Polymerization leads to vae copolymers.

Ethylene vinyl acetate is a type of plastic a polymer with a wide variety of uses both residential and industrial.

Ethylene vinyl acetate eva copolymers ethylene vinyl acetates are leading polymers for hot melt manufacturing due to their high versatility.

8 10 ethylene vinyl acetate eva.

Pvac copolymer emulsion glue of vinyl acetate vam and acrylic acid vaa polyacrylamide copolymer used as flocculation agent in water treatment polymethyl methacrylate is the clear break resistant sheeting sold as acrylic glass or simply acrylic sheet or under the trade name plexiglas perspex etc.

Vae copolymers form the basis for engineering different properties in the individual end application.

There are three different types of eva copolymer which differ in the vinyl acetate va content and the way the materials are used.

Ethylene vinyl acetate eva also known as poly ethylene vinyl acetate peva is the copolymer of ethylene and vinyl acetate the weight percent of vinyl acetate usually varies from 10 to 40 with the remainder being ethylene.

47 but elevated temperature and presence of some additives for example high amounts of clay cause the production of pungent acetic acid odor which is a product of thermal degradation.